Product Catalog

Product Overview

Solid Pad Mount Switchgear

The Solid Pad Mount Switchgearis designed for underground distribution systems with voltage classes up to 15kVand 27kV. This switchgear integrates a Circuit Breaker (CB)and a Load Break Switch (SW)to provide reliable switching and protection functions. The Circuit Breaker (CB)operates with a permanent magnetic actuatorand vacuum interrupters for efficient arc quenching, ensuring durability and maintenance-free operation. The Load Break Switch (SW)uses a spring toggle mechanismthat enables independent, quick closing and opening operations. The bushings are made of HCEP (Hydrophobic Cycloaliphatic Epoxy), delivering excellent insulation performance even in harsh environments, such as polluted or high-humidity areas. The epoxy molding structure enhances durability and reduces maintenance requirements. The switchgear supports two types of microprocessor-based controlsfor automated operations:Dual Protection Relay (ETR102/104):For metering and monitoring. RTU-Integrated Controller (ETCCU104):Includes communication, metering, monitoring, and recording capabilities.This product has been rigorously tested by accredited laboratories according to ANSI C37.60 standardsand specifications for underground distribution systems.

| Item | Specification | Item | Specification | |

|---|---|---|---|---|

| Rated Voltage [kV] | 25.8 | Operating Voltage [kV] | 60 (1분간) | |

| Rated Current [A] | 600 | Insulation Voltage [kV] | 78 | |

| Rated Breaking Current | 600 | Rated Short-time Withstand Voltage [kV] | 12.5 (1 second, Sym) | |

| Rated Frequency [Hz] | 60 | Rated Short-circuit Current [kA] | 32.5 (Peak) | |

| Surge Withstand Voltage [kV] | 125 (line-to-ground), 150 (between lines) | Operation Count | 200 operations (load break) / 5,000 operations (no load) | |

| Circuit Configuration | 33-D-A-125 | 44-D-A-125 | ||

| Control Function | Remote control & automation (FRTU compatible) | Dimensions [W x D x H, mm] | 1200 x 860 x 1100 | 1600 x 860 x 1100 |

| Weight [kg] | 450 | 690 | ||

25.8kV Solid Load Break Switch

The 25.8kV Solid Load Break Switch (LBS)is a three-phase switch designed for overhead line applications, offering a reliable solution for medium voltage power distribution. This switch utilizes a spring toggle mechanismfor operation and features vacuum interruptersfor effective arc quenching. The LBS can be operated either manually or automatically with an integrated motor drive for enhanced versatility. The bushings are made of HCEP (Hydrophobic Cycloaliphatic Epoxy), ensuring excellent insulation performance even in harsh climatic conditions and polluted environments. The tank and control cubicle are constructed from corrosion-resistant stainless steel, providing long-lasting durability in hot, humid, dusty, or corrosive conditions. For motorized operations, the LBS is equipped with a microprocessor-based controller, offering advanced functionalities such as metering, monitoring, recording, and communication. Its performance has been rigorously tested by accredited laboratories, fully meeting the requirements of the IEC 62271-103 international standard.

| Item | Specification | Item | Specification | |

|---|---|---|---|---|

| Rated Voltage [kV] | 25.8 | Creepage Distance [mm] | 645 | |

| Rated Current [A] | 630 | Control Circuitry | Control Voltage [V] | 1Ø 220V, 60Hz |

| Operation Method | Manual, Automatic | Control Power Supply [V] | DC 24V | |

| Frequency [Hz] | 60 | Allowable Voltage Range [%] | 85 ~ 110% | |

| Short-time Current [kA] | 12.5 (R.M.S) | Withstand Voltage [kV] | 2kV (1 minute) | |

| Peak Current [kA] | 32.5 (5 cycles) | Surge Withstand Voltage [kV] | 6 (1.2×50㎲) | |

| Surge Withstand Voltage [kV] | 150 (1.2×50㎲) | Weight [kg] | 97 | |

25.8kV Epoxy-Insulated Fault Interrupter (EFI)

The 25.8kV Epoxy-Insulated Fault Interrupter (EFI)is a one-shot circuit breaker designed for overhead distribution lines. It ensures the protection of upstream lines by interrupting fault currents up to 12.5kAand provides sectionalizing functionality by isolating faulted areas. The EFI employs a spring-charged mechanismand vacuum interrupters encapsulated within epoxy bushings for effective arc quenching. The bushings are constructed with HCEP (Hydrophobic Cycloaliphatic Epoxy), offering superior insulation performance even in harsh climatic and polluted environments. The interrupter's tank and control cubicle are made from corrosion-resistant stainless steel, ensuring durability in hot, humid, dusty, or corrosive conditions. A microprocessor-based control systemcan be integrated, supporting sectionalizing and communication functions. The EFI complies with international standards and has undergone comprehensive testing by accredited laboratories.

| Item | Specification | Item | Specification | |

|---|---|---|---|---|

| Rated Voltage [kV] | 25.8 | Surge Withstand Voltage [kV] | 150(1.2×50㎲) | |

| Rated Current [A] | 630 | Control Circuitry | Control Voltage [V] | AC 220V, 60Hz |

| Rated Frequency [Hz] | 60 | Control Power Supply [V] | DC 24V | |

| Short-time Current [kA] | 12.5 (R.M.S) | Allowable Voltage Range [%] | 85 ~ 110% | |

| Rated Short-circuit Current [kA] | 12.5 (R.M.S) | Withstand Voltage [kV] | 2kV (1 minute) | |

| Opening Duration [Cycle] | 3.0 (0.05 seconds) | Control Circuitry Surge Withstand Voltage [kV] | 6kV, 3kA | |

| Power Frequency Withstand Voltage [kV] | Dry: 60kV (1 minute), Wet: 50kV (10 seconds) |

Weight [kg] | Body | 150 |

| Communication Interface | RS-232 (For remote communication) | Control Box | 80 | |

25.8kV Polymer-Insulated Recloser

The 25.8kV Polymer-Insulated Recloseris designed for use on 22.9kV-Y overhead distribution lines. This recloser provides reliable protection and automatic reclosing functionality during fault conditions. It features vacuum interruptersand an epoxy insulation system, eliminating the need for SF6 gas and ensuring an environmentally friendly, maintenance-free design. The superior insulation performance of epoxy allows this recloser to operate reliably in general environments as well as in heavily polluted or salt-contaminated areas. The recloser tank and control cubicle are constructed with corrosion-resistant stainless steel, ensuring durability in harsh conditions such as heat, humidity, dust, or corrosive environments. The recloser utilizes a magnetic actuatoras its operating mechanism, simplifying internal components and reducing maintenance requirements. It guarantees a lifespan of 10,000 operations. The control unit incorporates an integrated FRTU-based digital system, providing advanced automation and fault management capabilities.

| Item | Specification | Item | Specification | |

|---|---|---|---|---|

| Rated Voltage [kV] | 25.8 | Surge Withstand Voltage [kV] | 150(1.2×50㎲) | |

| Rated Current [A] | 630 | Control Circuitry | Control Voltage [V] | AC 220V, 60Hz |

| Rated Frequency [Hz] | 60 | Control Power Supply [V] | DC 24V | |

| Short-time Current [kA] | 12.5 (R.M.S) | Allowable Voltage Range [%] | 85% ~ 110% | |

| Rated Short-circuit Current [kA] | 12.5 (R.M.S) | Withstand Voltage [kV] | Dry: 60kV (1 minute), Wet: 50kV (10 seconds) |

|

| Opening Duration [Cycle] | 3.0 (0.05 seconds) | Surge Withstand Voltage [kV] | 6, 3kA | |

| Closing Duration [Cycle] | 30 [0.5 초] | Weight [kg] | Body | 150 |

| Power Frequency Withstand Voltage [kV] | Dry: 60kV (1 minute), Wet: 50kV (10 seconds) |

Control Box | 80 | |

| Communication Interface | RS-232 (For remote communication) | |||

25.8kV Polymer-Insulated Directional Recloser

The Polymer-Insulated Directional Recloseris designed to operate on lines connected to distributed generation systems such as solar power, wind power, and small hydroelectric power. It prevents malfunction caused by reverse fault currents during power source-side faults by incorporating directional relay elements that detect the magnitude and direction of fault currents. This recloser is typically installed on the power supply side of the distribution network. Using vacuum interruption and epoxy insulation technology, the recloser eliminates the need for SF6 gas, making it environmentally friendly and maintenance-free by avoiding issues such as gas leakage or refilling. The superior insulation performance of epoxy allows it to be applied in both general and heavily polluted or salt-contaminated areas. The recloser tank and control cubicle are constructed with corrosion-resistant stainless steel. The operating mechanism adopts a magnetic actuator, simplifying internal components and ensuring easy maintenance. The recloser guarantees 10,000 open/close operations. The control unit features an integrated FRTU-based digital system with built-in directional relay functions.

| Item | Specification | Item | Specification | |

|---|---|---|---|---|

| Rated Voltage [kV] | 25.8 | Surge Withstand Voltage [kV] | 150 (1.2×50㎲) | |

| Rated Current [A] | 630 | Control Circuitry | Control Voltage [V] | AC 220V, 60Hz |

| Rated Frequency [Hz] | 60 | Control Power Supply [V] | DC 24V | |

| Short-time Current [kA] | 12.5 (R.M.S) | Allowable Voltage Range [%] | 85% ~ 110% | |

| Rated Short-circuit Current [kA] | 12.5 (R.M.S) | Withstand Voltage [kV] | Dry: 60kV (1 minute), Wet: 50kV (10 seconds) |

|

| Opening Duration [Cycle] | 3.0 (0.05 seconds) | Surge Withstand Voltage [kV] | 6, 3kA | |

| Closing Duration [Cycle] | 30 (0.5 seconds) | Weight [kg] | Body | 150 |

| Power Frequency Withstand Voltage [kV] | Dry: 60kV (1 minute), Wet: 50kV (10 seconds) |

Control Box | 80 | |

| Communication Interface | RS-232 (For remote communication) | |||

Polymer Lightning Arrester with Lead Wire

This polymer-insulated lightning arrester protects electrical equipment by limiting overvoltages from lightning strikes and circuit switching while interrupting follow currents. Its integrated lead wires enhance installation efficiency and corrosion resistance, while the polymer material ensures superior weather resistance, anti-tracking performance, and electrical reliability.

| Specification | Item |

|---|---|

| Frequency | 60Hz |

| Voltage | 18kV |

| Maximum Continuous Operating Voltage | 15.3kV |

| Nominal Discharge Current | 5kA |

| Reference Voltage / Reference Current | 22.9kV or higher / 1mA |

| Lightning Impulse Residual Voltage | 60kV or lower |

| Steep Impulse Residual Voltage | 66 kV or lower |

| High Current Discharge Capability | 65kA |

| Disconnector Operation Current | 20. 200. 800A |

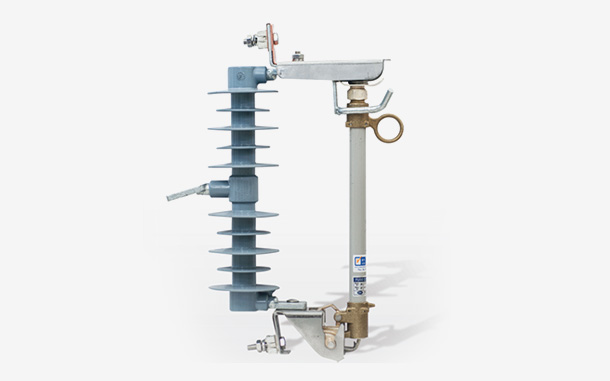

25.8kV Polymer Cutout Switch

This device is installed on the primary side of major equipment, such as pole-mounted and molded transformers, to protect the equipment from overcurrent caused by short circuits and other faults.

- - Simple and Durable Design: Easy to use with a robust and straightforward structure.

- - Exceptional Performance:Offers outstanding electrical and mechanical performance, leading global standardization efforts.

- - Leading Export Record:Recognized for the highest number of export destinations and volumes.

- - Cost-Effective:Lightweight and easy to handle, reducing construction and transportation costs. (Polymer COS)

- - High Strength and Durability:Made with polymer and FRP rod materials, providing excellent tensile strength and impact resistance, minimizing the risk of damage. (Polymer COS)

| Item | Specification | |

|---|---|---|

| Rated Voltage | 25.8kV | |

| Maximum Design Voltage | 27kV | |

| Rated Current | 100A | |

| Breaking Current | Asym | 10kA |

| Sym | 7.1kA | |

| Impulse Withstand Voltage | 125kV(1.25x50μS) | |